![]() BEST SOLUTION FOR YOUR BUSINESS

BEST SOLUTION FOR YOUR BUSINESS

VIET HUNG TECHNOLOGY CO.,LTD

Address: 5/313/6 Linh Nam street, Vinh Hung ward, Hoang Mai district, Hanoi city, Vietnam

Phone: +84 4 625 311 67 Fax: +84 4 625 311 67

Email: viet.hung.tech.ltd@gmail.com - sales@viethung-tech.vn

Andritz starts up new pulp line at Arkhangelsk's Novodvinsk mill, Russia

Written by Andy VuGRAZ, Austria, Feb. 2, 2016 (Press Release) -International technology Group ANDRITZ has successfully started up the pulp line delivered to JSC Arkhangelsk Pulp and Paper Mill (APPM) at the Novodvinsk mill, Russia. The new line features ANDRITZ green liquor technology for efficient pulp cooking, refining, and washing and produces 1,000 t/day of semi-chemical pulp for the production of corrugated board from birch and aspen.

Kadant receives orders of $7 million from two paper producers

Written by Andy VuWESTFORD, MA, Jan. 29, 2016 (Business Wire) -Kadant Inc. announced it received orders totaling $7 million from two paper producers in North America for chemical pulping equipment and a recycled fiber processing line. The chemical pulping equipment will be used to recover chemicals in the kraft pulping process and the recycled fiber processing system for the production of linerboard. The orders were booked in the fourth quarter of 2015 and are expected to ship in 2016.

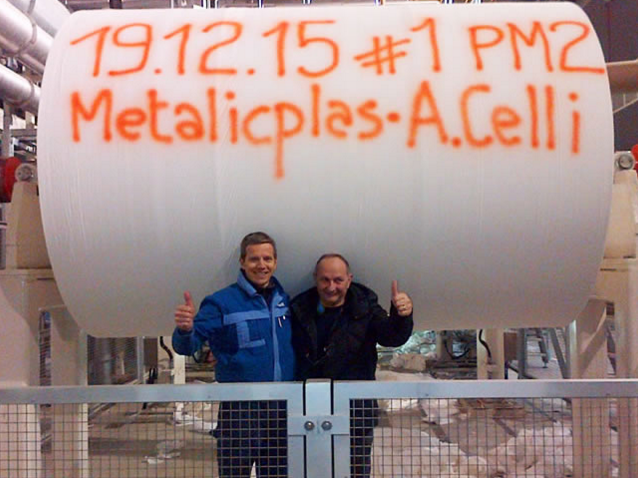

A.Celli Paper: the new tissue plant at Metalicplas (Pehart Tec Group) in Romania is up and running.

Written by Andy VuOn December 19, 2015, A.Celli Paper successfully concluded the start-up of the new high-speed Tissue Machine with a production capacity of 34,000 tons per year (110 tons per day) at Metalicplas (part of the Pehart Tec Group).

OMET installs the 750th tissue converting machine in the world

Written by Andy VuOMET is pleased to announce the accomplishment of the 750 installations of tissue converting machines globally since its foundation in 1963. It is the most evident result of OMET’s continuous search for innovation and of the trust customers all over the world tribute to a true market leader in the manufacturing of tissue converting machines.

The Canadian company Norbord recently announced that its Board of Directors has approved a $135 million (£95 million) investment to modernize and expand its OSB mill in Inverness, Scotland, nearly doubling its capacity to 720 million square feet (MMsf) (3/8-inch basis) (640,000 cubic metres).

DuraKnife is Valmet's patented chipper knife usable in almost all disc chippers. The custom-made sharp and strong DuraKnife ensures continuous high chip quality and longer change intervals for the knives, which improve the productivity of the chipper.

Suzano orders two tissue paper machines for Mucuri and Imperatriz mills

Written by Admin-tech(News from RISI) – Suzano Pulp and Paper has signed a $58 million order for two tissue paper machines (PM) to be installed at the company’s Mucuri and Imperatriz mills in northeast Brazil.

Each PM will have capacity to produce 60,000tpy and Suzano expects to start construction in May.

Tissue production is expected to start-up at Imperatriz in the third quarter of 2017 and at Mucuri in the fourth quarter of the same year.

Both mills will produce jumbo rolls to be supplied to toilet paper converters in the northeast region of Brazil.

Is there a better way of measuring energy efficiency in paper drying?

Written by Admin-techYes, there is. Rather than measuring the amount of steam that you use, measure the amount of steam that you lose. The steam consumption (amount of steam used per hour) is, by itself, an inadequate measure. A high value could be the result of either drying a lot of paper or venting a lot of steam. One is good. The other is bad. Indexing the amount of steam used with amount of water evaporated (pounds of steam per hour per pound of water evaporated) is a better metric, but significant amount of energy can easily be lost in the "noise" of this metric.

A better approach is to simply look for the steam losses. Specifically, look for steam that is vented to the atmosphere or vented to condenser tanks. Look for condensate that is dumped to a sewer and look for hot air that is exhausted from the dryer hood to the atmosphere. These are direct measurements of energy losses and they are direct indications of potential areas for energy recovery.

What common metrics are used for measuring paper drying efficiency?

Written byTwo common metrics for measuring paper drying efficiency are drying load (amount of water evaporated per hour) and steam consumption (amount of steam used per hour). The Technical Association of the Pulp and Paper Industry (TAPPI) recommends these metrics be indexed by the dryer surface area (resulting in pounds of water evaporated per hour per square feet of dryer surface area) and by the amount of water evaporated (resulting in pounds of steam per hour per pound of water evaporated). The indexed values are better indicators of dryer performance and overall energy efficiency of the drying process. Indexed values can be compared to similar machines as a benchmark of performance.

(News from RISI) – Brazil’s Suzano has announced a Real425 million investment in two tissue paper machines, each with capacity to produce 60,000tpy.

One PM will be installed at its Mucuri plant and the other one at the Imperatriz unit – both will produce jumbo rolls to be supplied to toilet paper converters in the northeast region of Brazil. Suzano CEO Walter Schalka said: “We want to sell jumbo rolls to national and international clients that want to operate in northeast Brazil, then they will be able to sell toilet paper wherever they want. This way, we’ll avoid the migration of jumbo rolls from southeast to northeast Brazil, which has a high cost.”

The executive added that Suzano has also obtained permit to convert the paper produced at its new tissue machines, but it doesn’t have plans to do it in the short term. The company plans to start up the Imperatriz tissue PM at the end of the third quarter of 2017 and the Mucuri PM at the fourth quarter of 2017.